Design Features:

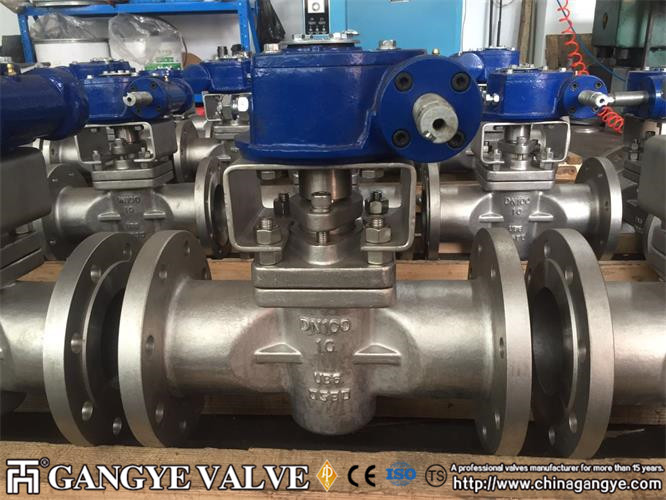

Nominal Size Range: NPS 1/2” ~ 14”

Pressure Rating: Class 150LB ~ 900LB

Connection: Flange (RF, FF, RTJ), Butt Welded (BW), Socket Welded (SW)

Design: API 599, API 6D

Pressure-temperature rating: ASME B16.34

Face-to-face dimensions for butt weld and flanged valves: ASME B16.10

Flange design: ASME B16.5

Butt welding design: ASME B16.25

All valves are designed to comply with the requirements of ASME B16.34, and the ASME as well as customers’ requirements as applicable.

Actuators:

Gear, Electric, Cylinder, Pneumatic, Hydraulic, Lever, Chain wheels

Body Material:

A216-WCB (Carbon Steel), A217-WC6 (1-1/4Cr-1/2Mo), A217-WC9 (2-1⁄4Cr–1Mo), A217-C5 (5Cr–1⁄2Mo), A217-C12 (9Cr–1Mo), A352-LCB (Carbon Steel), A352-LCC (Carbon Steel), A351-CF8M (18Cr–9Ni–2Mo), A351-CF3M (18Cr–9Ni–2Mo)

Quality Assurance (QA):

Every step from procurement through production, welding, assembly, testing, and packaging is in accordance with quality programs and procedures (ASME Section III manual and ISO 9001 manual).

Quality Control (QC):

The QC is responsible for all aspects of quality, from receiving of material to control of machining, welding, nondestructive examination, assembly, pressure testing, cleaning, painting, and packaging.

Pressure Testing:

Each valve is pressure tested in accordance with API 6D, API 598, or special customers’ requirements as applicable.