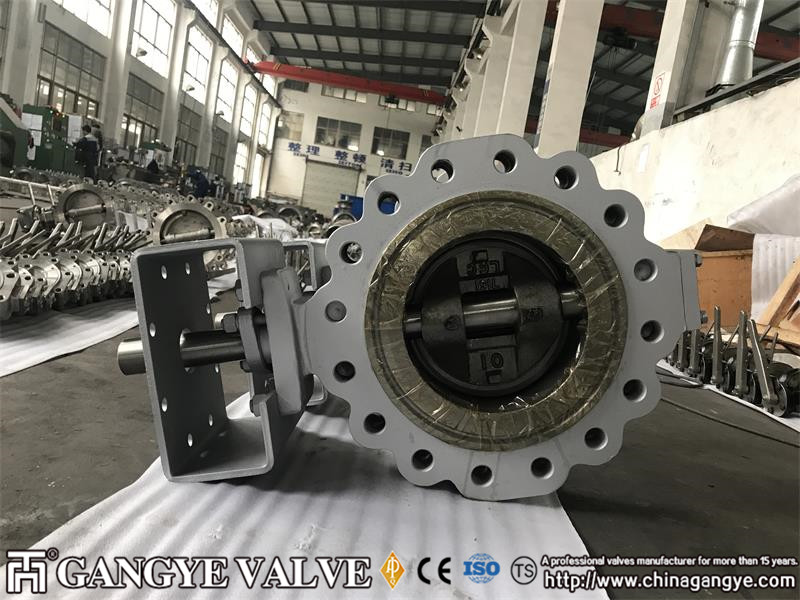

Premium Double Eccentric Lug-Type Butterfly Valves

High-Performance Double Eccentric Butterfly Valves | Zero Leakage Design

High-Performance Double Eccentric Butterfly Valves | Zero Leakage Design

High-Performance Double Eccentric Butterfly Valves | Zero Leakage Design

High-Performance Double Eccentric Butterfly Valves | Zero Leakage Design

Premium Double Eccentric Lug-Type Butterfly Valves

Industry-leading double eccentric butterfly valves with fire-safe API 607 certification. Bidirectional sealing, -196°C to 815°C operation. NSF-compliant for chemical/steam applications.

Engineered for Extreme Conditions | API 609 & NACE MR0103 Certified

Core Technology

Our dual-offset design combines two precision eccentricities:

- Radial Eccentricity: Spindle offset from sealing surface center

- Axial Eccentricity: Spindle offset from pipeline centerline

This patented geometry creates cam-actuated sealing that eliminates seat friction during operation. Benefits include:

✅ 90% torque reduction vs conventional valves

✅ Zero-leakage performance (API 598 certified)

✅ 10-year service life in abrasive media

Key Specifications

| Parameter | Specification |

|---|---|

| Size Range | 2″-128″ (50-3200mm) |

| Pressure Class | 150# to 300# (ASME B16.34) |

| Temp Range | -196°C to +815°C (-320°F to +1500°F) |

| Drives | Manual/Gear/Pneumatic/Electric (ISO 5211) |

Industry-Leading Applications

✔ Fire Protection Systems (API 607/ISO 10497 certified)

✔ LNG Cryogenic Transfer (-196°C low-temp design)

✔ Chemical Processing (NACE MR0103 compliant)

✔ Power Generation (1500°F steam-rated seats)

✔ Oxygen Service (ASTM G93 cleaning protocol)

Proprietary Seal System

- Self-Compensating Lip Seal: Automatically adjusts for thermal/pressure changes

- Quick-Change Seat Cartridge: Replace seals in 15 mins without full disassembly

- Bidirectional Sealing: Maintains bubble-tight closure at 300# pressure

Safety Features

🔒 Blowout-proof stem retention

🔒 Anti-static EN 13789 compliance

🔒 X-ray inspected welds (ASME Section IX)

Global Certifications[Badge icons] API 609 • ISO 5211 • EN 1092 • NACE MR0103

Optimized for Your Industry

| Medium | Recommended Configuration |

|---|---|

| Chlorine | Monel-seated RPTFE seals |

| Sulfuric Acid | Hastelloy C276 disc coating |

| Abrasive Slurries | Tungsten carbide edge treatment |

| Oxygen | ASTM G93 degreased assembly |

Why Choose Us?

- 30% Faster Delivery: Regional warehouses in USA/EU/Middle East

- Custom Engineering: ASME/NACE-compliant modifications

- Lifetime Technical Support: On-call fluid system experts

Localization Keywords (Priority Order):

- High performance butterfly valves

- API 609 dual eccentric valves

- Fire-safe lug type valves

- Cryogenic butterfly valves

- Zero leakage industrial valves

- NACE compliant chemical valves

- High temperature steam valves

- Oxygen service butterfly valves

- North America: Emphasize API/ASME compliance

- Europe: Highlight EN/ISO certifications

- Middle East: Feature fire-safe LNG applications

- Asia-Pacific: Focus on chemical/pharma compliance

- CTA Section

Need a Valve That Outperforms Competitors?

☑️ Custom configurations for extreme media

☑️ 24/7 technical support

☑️ 2-year warranty with lifetime service📞 Contact Our Engineers Now 📧 sales@chinagangye.com for a Free Application Analysis!