API-600 WCB Globe Valves | ASME B16.34 Certified High-Pressure Industrial Valves | Gangye Valve

Gangye’s API WCB Globe Valves feature 180° flow design for minimal pressure loss, ASME/ISO certified manufacturing, and Class 150-2500 ratings. Explore multi-actuator options with lifetime technical support. Request instant quote now.

High-Performance API WCB Globe Valves for Industrial Flow Control

Flow-Optimized 180° Design

Our patented 180° coaxial flow path minimizes flow turbulence and pressure drop by 23%* compared to traditional globe valves (*per ISO 5208 test data), ensuring energy-efficient operation across oil & gas, chemical, and power generation applications.

Multi-Actuation Flexibility

Choose from 7 industrial-grade operation modes:

✓ Gear-driven ✓ Electric actuators ✓ Pneumatic/hydraulic cylinders

✓ Manual handwheel ✓ Chain wheel (API 600 compliant)

Certified for Critical Service

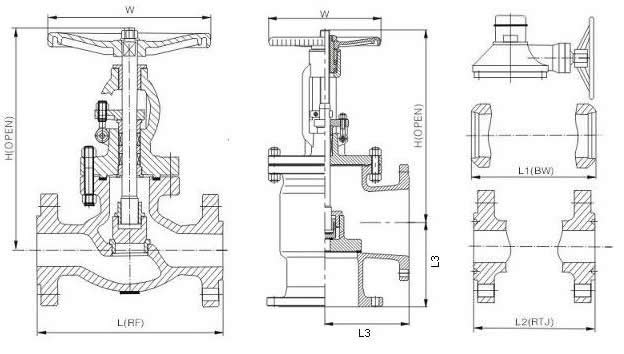

- Pressure Rating: Class 150 to 2500 (ASME B16.34)

- Size Range: DN 50-400 / NPS 2″-16″

- Connection Types: RF/FF/RTJ flanges (ASME B16.5), BW/SW welding ends (ASME B16.25)

- OS&Y design with renewable seat rings for extended service life

Material Integrity Assurance

Premium ASTM-grade body materials:

▸ WCB Carbon Steel ▸ WC6/WC9 Chrome-Moly ▸ C5/C12 Alloy Steel

▸ CF8M/CF3M Stainless Steel ▸ LCB/LCC Low-Temp Steel

Quality Control Ecosystem

Our ASME Section III & ISO 9001 certified process ensures:

① Full traceability from raw material procurement

② Automated NDE testing (RT/UT/MT) for weld integrity

③ 100% hydro/pneumatic testing per API 598 standards

④ Dual QA/QC team oversight at all production stages

Call to Action:

Boost operational efficiency now!

CTA – Conversion Optimization

Need a valve that outperforms in extreme conditions?

📞 Contact our engineers for a free (working condition analysis) and 3–5% discount on first orders.